friction test engineer|coefficient of friction testing equipment : factories 1,229 Friction Test jobs available on Indeed.com. Apply to Test Engineer, Engineer, Security Engineer and more! web26 de jan. de 2015 · Listen to Ciara I Bet MP3 song. I Bet song from the album I Bet is released on Jan 2015. The duration of song is 04:48. This song is sung by Ciara. Related Tags - I Bet, I Bet Song, I Bet MP3 Song, I Bet MP3, Download I Bet Song, Ciara I Bet Song, I Bet I Bet Song, I Bet Song By Ciara, I Bet Song Download, Download I Bet .

{plog:ftitle_list}

Resultado da 03/12/2022 • 00:53. Em Notícias. A A. O N1 Entretenimento entrevista o diretor e roteirista, Beto Ribeiro, da produtora Medialand. O entrevistado revela com exclusividade, .

runway friction testing equipment

170 Friction Test Engineer jobs available on Indeed.com. Apply to Site Reliability Engineer, Platform Engineer, Senior Software Engineer and more!1,229 Friction Test jobs available on Indeed.com. Apply to Test Engineer, .Today’s top 1,000+ Friction Material Test Engineer jobs in United States. Leverage your professional network, and get hired. New Friction Material Test Engineer jobs added daily.1,229 Friction Test jobs available on Indeed.com. Apply to Test Engineer, Engineer, Security Engineer and more!

Looking for Test Engineer Friction Material Jobs near you? Discover 51,716 job openings. Don't miss your next opportunity.Today’s top 16,000+ Friction Engineer jobs in United States. Leverage your professional network, and get hired. New Friction Engineer jobs added daily.

good moisture meter for pine woodworking sawmillcreek

What does a Friction Engineer do? Read the Friction Engineer job description to discover the typical qualifications and responsibilities for this role. Portable, handheld instant friction testers can be used on angled or contoured surfaces to optimise the metal forming process, protect equipment and improve product quality.ADMET material testing systems will accurately and reliably perform friction testing and automatically calculate properties such as the static coefficient of friction and the dynamic coefficient of friction.Coefficient of Friction Testing is a critical procedure in the field of engineering and material science. It is a method used to measure the frictional characteristics between two surfaces, providing valuable data that can influence the design, .

Friction testing is a cornerstone of modern engineering and tribology – empowering engineers to optimise lubrication systems, reduce energy consumption, extend the lifespan of critical components, and enhance overall . Zero Friction Cycling, run by former policeman Adam Kerin, presents itself as a trusted source for friction-reducing products, but behind the scenes, a lack of engineering knowledge and unverified testing methods raise red flags. Despite requesting sensitive industry data without doing foundational research, Kerin's approach appears more focused on .

The Model 1158 T0-4 Test Machine (Model 1158) conducts tests for performance and durability of wet friction clutch plates, spacer plates and transmission fluids. This incremental inertia dynamometer uses the kinetic energy of the rotating . Effect of Friction between Sample and Platen. There are also concerns about the effect of friction. This is potentially important, since one outcome of friction is that the stress and strain fields become non-uniform - see the simulation below, so that the nominal stress-strain curve cannot be converted to a true version via use of the analytical equations (even if the .Single Source for Testing Equipment and Services Across America and Around the World Asia œ Europe œ North America œ South America Link Engineering Company 734-453-0800 www. linkeng.com The Model 1158 T0-4 Test Machine conducts tests for performance and durability of wet friction clutch plates, spacer plates and transmission fluids.Slip is the opposite of friction, so a high COF gives a low slip factor. Typical graph showing coefficient of friction test: We provide force measurement instruments and materials testing machines for friction testing. Request more information to see how we can help you with a friction testing solution that suits your needs.

The Model 1158 T0-4 Test Machine (Model 1158) conducts tests for performance and durability of wet friction clutch plates, spacer plates and transmission fluids. This incremental inertia dynamometer uses the kinetic energy of the rotating mass that is absorbed by the reaction of a rotating friction disc and an opposing stationary steel plate.

About EJ: We are the leader in the design, manufacture, and distribution of access solutions for water, sewer, drainage, telecommunications, and utility networks. EJ is a family-owned company with corporate headquarters located in East Jordan, Michigan, where the company was founded in 1883. Globally, we employ over 2,500 people, have operations in 13 countries and sell our .

It provides information about soil stratigraphy and relative density and is widely used in geotechnical engineering. Cone Penetration Test (CPT): CPT involves pushing a cone-shaped penetrometer into the ground at a constant rate to measure cone resistance and sleeve friction. It provides data on soil strength, cohesion, and friction angle.Oct 23,2024 - Friction Engineering Mechanics is created by the best Civil Engineering (CE) teachers for Civil Engineering (CE) preparation. . Here comes the role of the chapter-wise Test of Friction. EduRev provides you with three to four tests for each chapter. These MCQs (Multiple Choice Questions) for Civil Engineering (CE) are designed to .specification of interface friction testing and how to interpret and use generated test results has become a crucial part of an engineer's job. In fact, the cost for not understanding ASTM D 5321 and D 6243 tests and test data can be enormous. Unfortunately, the .

measuring the coefficient of friction

While there is a lot of technology available to engineers for controlling friction and wear, leading tribologists say friction and wear are complex and not fully understood. One highly regarded engineering professor maintains that good mechanical design related to friction starts with practicality. He advocates a few simple guidelines, including: “Prefer pivots to slides, and . Typical areas of friction studies include: Surface engineering . . . When material surfaces are in mechanical contact and slide against each other, complex microscopic interactions occur between the surfaces that lead to friction and wear. . Choosing a friction testing platform that can be quickly adapted for different test conditions and .

Work with us to find the right equipment for your friction testing Friction Testing Universal Testing Systems Friction testing allows quality control professionals to determine the coefficients of starting and sliding friction of materials such as plastic films, sheeting, household items, conveyor belts, and more. ADMET material testing systems will accurately and reliablyIn November 2017, Link Engineering Company acquired the Krauss product line and brand. Going forward, LINK will be offering the Krauss product line of test equipment for friction material performance, quality control, and wear .The general structure of plain/journal bearings. Application of friction to analyze the forces and moments involved in the movement of a (plain) bearing. 6.6: Disc Friction Friction in common disc-shaped mechanisms. Calculating moment based on friction for such discs. 6.7: Belt Friction Determining friction in flat-belt and V-belt pulley systems.Pavement friction tester that meets the requirements of ASTM E274; Digital survey vehicles (DSVs) . Leveraging extensive experience in pavement engineering and a fleet of pavement testing equipment and related .

The friction-transfer test is partially destructive and can estimate the rock uniaxial compressive strength (UCS) using experimental equations or a previously prepared calibration graph. In this study, some engineering properties of seven types of limy rocks from Qom formation, collected from Hamadan province, were estimated using friction .Sotter Engineering Corporation provides specialized, certified, engineer-stamped floor, tile, and roadway dynamic coefficient of friction (DCOF) testing, ASTM E303 (updated in 2022) road and floor slip resistance testing, SCOF tile testing (ASTM C1028 and ANSI B101.1 – reliable in dry condition only), and we also sell floor floor friction .

Kinetic Coefficient of Friction (μk): The kinetic COF is the resistance to movement between the materials after they are set in relative motion. ASTM D1894 is the most frequently used testing standard, while custom testing and equipment are available.COF measurement is commonly performed for plastic films, sheeting, lubricants, paper, etc. Scope

More.Project Engineer, Dynatest Consulting Pavement Policy & Design Engineer 8. Performing Organization Report WisDOT Report # WI-06-12 9. . Friction testing was performed at 3,394 sites in accordance with ASTM E274 using a Dynatest 1295 Pavement Friction Tester. Testing was conducted using the ASTM E501 standard rib tire and skid numbers were .

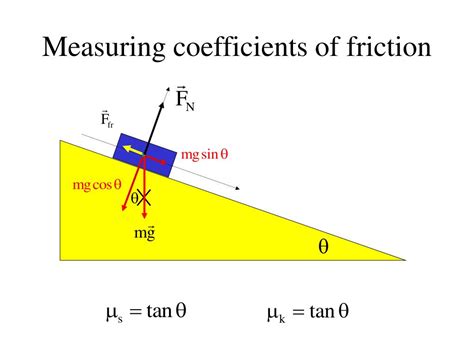

Develop, test, iterate. Repeat. Countless miles logged and hours spent toiling away, all for good reason: eliminating friction. Friction buildup throughout the system reduces how easily your suspension responds to trail features. It’s the momentary binding as you move through travel that adds harshness to your ride, reducing small bump compliance and causing you to work harder . As a result, understanding the specification of interface friction testing and how to interpret and use generated test results has become a crucial part of an engineer’s job. In fact, the cost for not understanding ASTM D 5321 and D 6243 tests and test data can be enormous.Static friction is friction between two or more solid objects that are not moving relative to each other. For example, static friction can prevent an object from sliding down a sloped surface. The coefficient of static friction, typically denoted as μ s, is .

friction testing methods

Since 1935, we’ve helped establish the brake testing specs and methodologies that have become industry norms. Deep knowledge and expertise goes into everything we do — from the products we engineer to every test we run. Because our labs use the same brake and friction-material testing equipment you do, we’re LINK customers, too.

Wear testing is a method used to evaluate the wear resistance and performance of materials under specific conditions, simulating real-world applications. This process is essential for understanding how materials will behave when subjected to friction and abrasion, helping engineers design more durable products. It involves assessing wear mechanisms such as .

friction tester machine by dayton

Resultado da 2 de abr. de 2019 · Muito reservada em relação a sua vida pessoal, Cássia Kis foi clicada em um momento raro, na noite desta terça-feira (2). A atriz .

friction test engineer|coefficient of friction testing equipment